S&P USA brand TDB - Industrial Belt Drive Tube Axial Duct Fan CFM Range: 1,489-17,497 (12"-30" Dia) Explosion Proof Available - 34 Products

Brochure (6.18 mb)

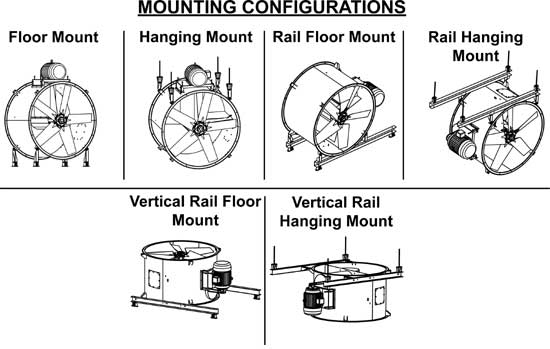

Brochure (6.18 mb) Mounting Arrangements and Inspection Door options (1.34 mb)

Mounting Arrangements and Inspection Door options (1.34 mb) Installation and Operation Manual (364kb)

Installation and Operation Manual (364kb)

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Model Features

• Rated up to 75,490 CFM in static pressure applications up to 1-1/2” w.g.

• 12 sizes ranging from 12 to 60” propeller diameters

• Motor and drives are located outside of the airstream

• Belt drives permit easy performance adjustments when needed

• Continuously welded and epoxy painted steel housing

• AMCA Air & Sound Certified

• cULus Listed

Model Overview

Construction/Specification Checklist

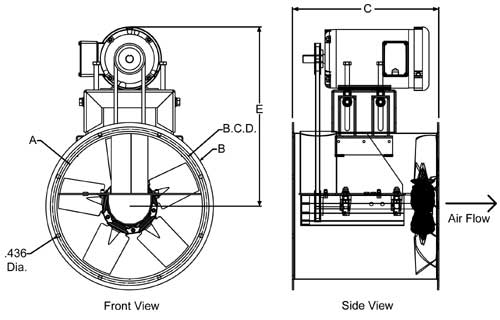

Fan Housing

• Heavy-gauge rolled steel construction.

• Integral inlet and outlet flanges with mounting holes.

• Continuous welded and epoxy coated.

• Belt and bearing tube.

• Removable bearing cover for ease of maintenance.

• Eight mounting supports welded to each fan.

• Adjustable motor base for belt tensioning.

• Extended lube lines.

Propeller

• Aluminum airfoil propeller.

• Blades are pitched for optimum efficiency.

• Statically balanced

Drives

• Sized for minimum 150% of drive horsepower.

• Single belt adjustable pitch sheaves through 5HP.

• Multiple belt fixed pitch sheaves 7-1/2HP and above.

• Adjustable tension rods for belt adjustment.

• Nonstatic oil resistant v-belts.

• Keyed, turned, ground and polished shafts.

Bearings

• Bearings are designed for minimum 200,000 hour life, L50.

• Cast iron self-aligning pillow block ball bearings.

• Bearings are sealed and pre-lubricated.

Motors

• One year motor warranty.

• Brands are nationally recognized and locally serviced.

• NEMA base-mounted motors are standard.

• Open drip-proof construction is standard.

• Premium-efficiency, explosion proof, totally enclosed fan cooled (TEFC) and corrosion duty motors can be specified.

Certifications

• AMCA Air and Sound Certified

• cULus 705 Listed

Entire Fan Unit

• Factory assembled and tested prior to shipment for quality assurance.

NOTE: This Product Is Not Available to Ship to Canada.

| BLADE DIAMETER | MODEL# |

Max RPM |

H.P. | CFM @ STATIC PRESSURE | |||||||

| 0" | 1/8" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | 7/8" | ||||

| 12" | TDB12-1/4 | 1700 | 1/4 | 1489 | 1341 | 1104 | -- | -- | -- | -- | -- |

| TDB12-1/3 | 1875 | 1/3 | 1642 | 1511 | 1335 | -- | -- | -- | -- | -- | |

| TDB12-1/2 | 2150 | 1/2 | 1883 | 1771 | 1638 | 1450 | -- | -- | -- | -- | |

| TDB12-3/4 | 2425 | 3/4 | 2124 | 2025 | 1916 | 1783 | 1593 | -- | -- | -- | |

| 16" | TDB15-1/4 | 1275 | 1/4 | 2189 | 1965 | 1696 | 1355 | -- | -- | -- | -- |

| TDB15-1/3 | 1425 | 1/3 | 2446 | 2250 | 2023 | 1755 | 1424 | -- | -- | -- | |

| TDB15-1/2 | 1625 | 1/2 | 2790 | 2621 | 2432 | 2219 | 1975 | 1688 | 1349 | -- | |

| TDB15-3/4 | 1875 | 3/4 | 3219 | 3075 | 2917 | 2746 | 2560 | 2352 | 2118 | 1852 | |

| TDB15-1 | 2075 | 1 | 3433 | 3294 | 3145 | 2986 | 2815 | 2627 | 2421 | 2192 | |

| 18" | TDB18-1/4 | 1125 | 1/4 | 2823 | 2483 | 2089 | -- | -- | -- | -- | -- |

| TDB18-1/3 | 1275 | 1/3 | 3199 | 2902 | 2580 | 2172 | -- | -- | -- | -- | |

| TDB18-1/2 | 1450 | 1/2 | 3638 | 3379 | 3106 | 2803 | 2414 | -- | -- | -- | |

| TDB18-3/4 | 1650 | 3/4 | 4140 | 3914 | 3678 | 3431 | 3156 | 2820 | 2303 | -- | |

| TDB18-1 | 1825 | 1 | 4579 | 4377 | 4164 | 3947 | 3717 | 3462 | 3159 | 2748 | |

| TDB18-1 1/2 | 2075 | 1 1/2 | 5207 | 5031 | 4844 | 4656 | 4464 | 4262 | 4044 | 3802 | |

| 20" | TDB20-1/3 | 1150 | 1/3 | 3728 | 3302 | 2812 | -- | -- | -- | -- | -- |

| TDB20-1/2 | 1300 | 1/2 | 4214 | 3840 | 3436 | 2940 | -- | -- | -- | -- | |

| TDB20-3/4 | 1450 | 3/4 | 4701 | 4366 | 4017 | 3624 | 3131 | -- | -- | -- | |

| TDB20-1 | 1675 | 1 | 5430 | 5142 | 4846 | 4534 | 4188 | 3779 | 3238 | -- | |

| TDB20-1 1/2 | 1925 | 1 1/2 | 6240 | 5990 | 5736 | 5475 | 5200 | 4903 | 4570 | 4179 | |

| TDB20-2 | 2075 | 2 | 6727 | 6495 | 6260 | 6020 | 5772 | 5511 | 5229 | 4917 | |

| 24" | TDB24-1/2 | 950 | 1/2 | 5662 | 5056 | 4351 | -- | -- | -- | -- | -- |

| TDB24-3/4 | 1125 | 3/4 | 6705 | 6201 | 5655 | 5014 | 4095 | -- | -- | -- | |

| TDB24-1 | 1250 | 1 | 7450 | 7001 | 6521 | 5996 | 5370 | 4479 | -- | -- | |

| TDB24-1 1/2 | 1425 | 1 1/2 | 8493 | 8103 | 7690 | 7258 | 6785 | 6243 | 5558 | -- | |

| TDB24-2 | 1550 | 2 | 9238 | 8882 | 8506 | 8117 | 7705 | 7256 | 6744 | 6117 | |

| TDB24-3 | 1775 | 3 | 10579 | 10274 | 9946 | 9614 | 9272 | 8914 | 8534 | 8121 | |

| 30" | TDB30-1/2 | 750 | 1/2 | 8202 | 7008 | 5319 | -- | -- | -- | -- | -- |

| TDB30-3/4 | 850 | 3/4 | 9295 | 8267 | 7002 | 5007 | -- | -- | -- | -- | |

| TDB30-1 | 950 | 1 | 10389 | 9482 | 8441 | 7094 | 4911 | -- | -- | -- | |

| TDB30-1 1/2 | 1100 | 1 1/2 | 12029 | 11256 | 10414 | 9447 | 8244 | 6532 | -- | -- | |

| TDB30-2 | 1200 | 2 | 13122 | 12417 | 11666 | 10834 | 9871 | 8678 | 7027 | -- | |

| TDB30-3 | 1375 | 3 | 15036 | 14424 | 13787 | 13107 | 12366 | 11538 | 10576 | 9394 | |

| TDB30-5 | 1600 | 5 | 17497 | 16972 | 16436 | 15877 | 15289 | 14664 | 13989 | 13249 | |

Customer Reviews

(0.00)stars out of 5

(0.00)stars out of 5